If building a personal protection mask that could be mass produced to fight the coronavirus pandemic was a puzzle, Joshua Kim was determined to figure it out.

The 25 year-old is the Senior Designer and Program Coordinator with the Department of Surgery at the Medical University of South Carolina in Charleston.

“That moment was an epiphany moment,” says Kim. “It was a great moment.”

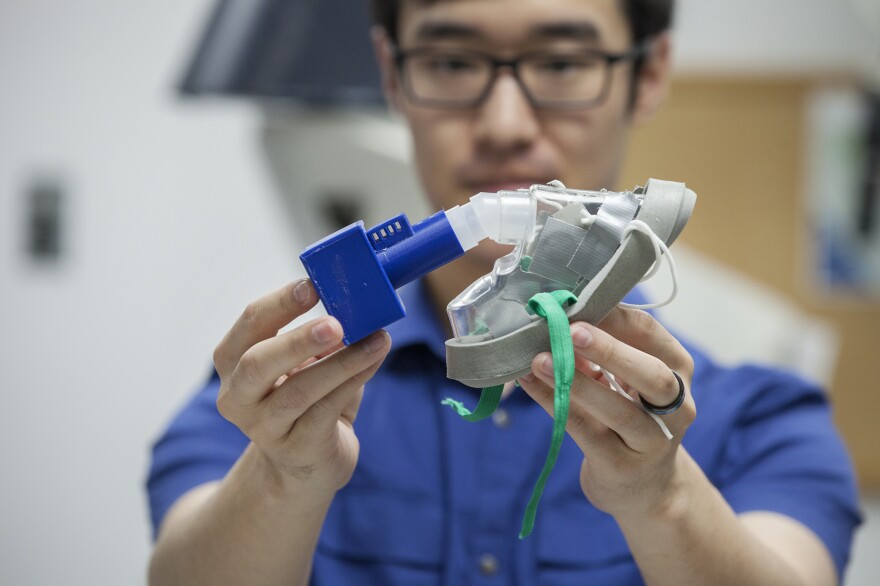

It was the moment Kim realized he could use an air filter, like those commonly found in home improvement stores, to build a respirator for a mask mimicking the N95 now in demand.

“They filter out viruses too," says Kim.

So, he bought a HEPA filter and got to work using his 3D printer.

"I just started 3D printing at home," he says. "I made a cartridge prototype in 15 hours and just started collaborating with everyone else on how to get it onto a 3D printed mask."

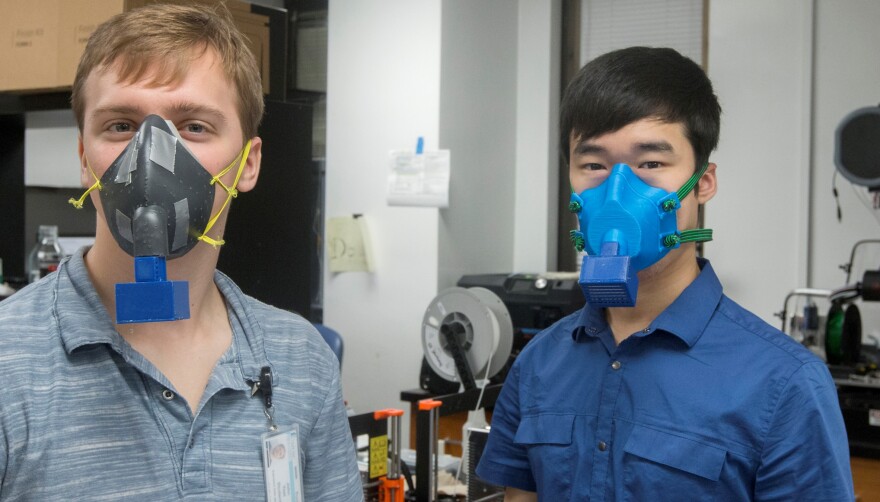

Dr. Michael Yost, the Vice Chairman of Surgery for Research at MUSC, was also strategizing with a team to make a 3D printable mask. This, while his 23-year-old son John collaborated with Kim on the respirator cartridge.

“I think in about three days we had prototypes that we were in the hospital testing,” Dr. Yost says.

“The biggest problem with our first prototype was every time you breathed in and out the mask would move,” says Kim. “You’re actually getting air from the environment which defeats the purpose of having a filter cartridge.”

So, the team added a foam seal around the mask, and it passed rigorous hospital testing. It was then time to share the 3D printing files with the public.

“That was part of the design criteria, to make it so as many people as possible could put these things together,” says Dr. Yost.

MUSC has posted a link to the files and an assembly guide on its website. You'll find it here. https://web.musc.edu/innovation/covid-19-innovation

The site gives step by step instructions on how to print the 3D components and put them together. If you don't have a 3D printer, Kim says they are easily found at local libraries, colleges and high schools. Some even sell online for a couple hundred dollars.

Kim says it can take 10 to 20 hours to print both the mask and cartride. They cost roughly $5 to $15 dollars depending upon how many are made at one time.

For Kim, creating the respirator cartridge to fit on an existing or newly printed mask was all about problem solving. He was inspired by NASA engineers who brought the Apollo 13 crew safely home using among other things, duct tape.

“I like to tinker,” Kim says. “I figured during this time of social distancing; this is one of the best times to be productive as we have all of this kind of news time to fill up with things we can do.”

The MUSC team hopes people will take the time to make 3D printable masks to arm those on the frontlines fighting the coronavirus, as well as themselves.